Autodesk® Moldflow® software provides simulation tools for injection mold design, plastic part design, and validating and optimizing the injection molding process. The software guides designers, mold makers, and engineers through simulation setup and results interpretation to show how changes to wall thickness, gate location, material, and geometry affect manufacturability. Key features of Moldflow include

|

|

Real-Time Plastic Injection Molding Simulation

With Autodesk Moldflow 2012, you can dynamically evaluate a range of potential plastic part designs in a fraction of the time it takes to perform a standard simulation, helping you pinpoint the best design more quickly.

|

|

|

Transient Cooling of Plastic Injection Molds

Determine temperature variation in an injection mold during a plastic injection molding cycle. Predict the number of cycles required from production startup until the mold reaches a stable temperature.

|

|

|

Fiber Orientation in Plastic Part Designs

More accurately predict the orientation of short and long glass fibers, which are critical to the overall performance, shape, strength, and weight of plastic parts.

|

|

|

Design Optimization

With Autodesk® Moldflow® Insight 2012 software, the Design of Experiments (DOE) capabilities are expanded to all mesh types, molding processes, and simulation tools—helping to better optimize the design and manufacturing of injection-molded plastic parts.

|

|

|

Shrinkage and Warpage Simulation

Evaluate plastic part and injection mold designs to help control shrinkage and warpage based on grade specific materials and processing parameters.

Learn More

|

|

|

Thermoset Flow Simulation

Simulate thermoset injection molding, RIM/SRIM, resin transfer molding, and rubber compound injection molding.

Learn More

|

|

|

Geometry Modification

With Autodesk Moldflow 2012, you can use Autodesk® Inventor® Fusion to modify or simplify geometry more quickly and easily, helping to optimize plastic part designs for manufacturability and quality as fast as possible.

|

|

|

Specialized Molding Processes

Simulate a wide range of plastic injection molding processes and specialized process applications.

Learn More

|

|

|

CAD Interoperability Tools

Use tools for native CAD model translation and optimization.

Learn More

|

|

|

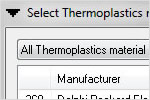

Material Data

Improve simulation accuracy with precise material data on over 8600 grade specific plastics. Get additional materials tested, expert data-fitting services, and extensive material databases with the Autodesk® Moldflow® Plastics Labs.

Learn More

|

|

|

CAE Data Exchange

Validate and optimize plastic part designs using tools to exchange data with structural simulation software. CAE data exchange is available with Autodesk® Simulation, ANSYS®, and Abaqus® structural simulation software to help predict the real-life behavior of plastic parts by using as-manufactured material properties.

|

|

|

Autodesk Moldflow Communicator

Collaborate with manufacturing personnel, procurement engineers, suppliers, and external customers using Autodesk® Moldflow® Communicator software. The Autodesk Moldflow Communicator results viewer enables you to export results from Autodesk Moldflow software so stakeholders can more easily visualize, quantify, and compare simulation results.

|

Autodesk® Moldflow® simulation software provides injection molding simulation tools for validating and optimizing plastic parts, injection molds, and the injection molding process. The software guides designers, mold makers, and engineers through simulation setup and results interpretation to show how changes to wall thickness, gate location, material, and geometry affect manufacturability. Autodesk Moldflow offers geometry support ranging from thin-walled parts to thick and solid applications and helps you to experiment with “what-if” scenarios before finalizing a design.